Waveguide Terminations & Dummy Loads |

|---|

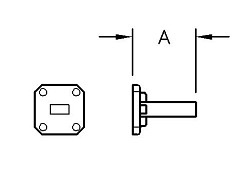

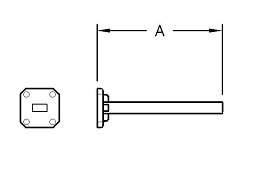

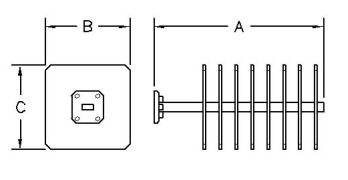

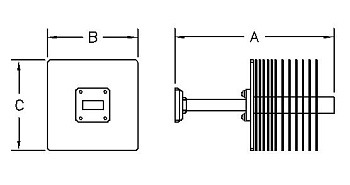

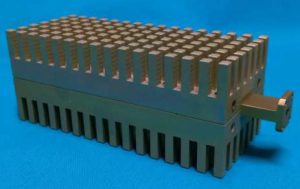

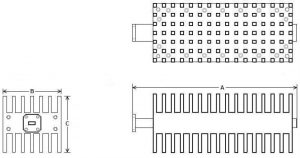

Low, Medium and High Power Terminations

Narda-MITEQ manufactures a tremendous selection of Short, Low, Medium, and High Power Terminations for Rectangular Waveguides that do not require Forced Air Cooling. Double Ridge Waveguide Terminations are also available.

We offer a complete line of waveguide terminations in all waveguide sizes and power levels.

Please call us and discuss your needs with one of our design engineers.

|

* The Standard Model Numbers above are the most common parts ordered for size, material and flange. However, these models can easily be altered for your needs by using the Model # code system at left. |

||||||||||||||||||||||||||||||

|

* The Standard Model Numbers above are the most common parts ordered for size, material and flange. However, these models can easily be altered for your needs by using the Model # code system at left. |

||||||||||||||||||||||||||||||

|

* The Standard Model Numbers above are the most common parts ordered for size, material and flange. However, these models can easily be altered for your needs by using the Model # code system at left. |

||||||||||||||||||||||||||||||

|

* The Standard Model Numbers above are the most common parts ordered for size, material and flange. However, these models can easily be altered for your needs by using the Model # code system at left. |

||||||||||||||||||||

|

* The Standard Model Numbers above are the most common parts ordered for size, material and flange. However, these models can easily be altered for your needs by using the Model # code system at left. |

||||||||||||||||||||

|

* The Standard Model Numbers above are the most common parts ordered for size, material and flange. However, these models can easily be altered for your needs by using the Model # code system at left. For flanges other than shown, please contact the factory. Note: All 980 series terminations are aluminum construction only. |

||||||||||||||||||||