Passive Dehydrator Dryer for Waveguide |

|---|

Waveguide Passive Dehydrators

Narda-MITEQ manufactures a selection of Waveguide Passive Dehydrators ranging from WR28 to WR650. The passive waveguide dehydrator is a low-maintenance, reliable method to remove moisture from waveguide systems. It uses a canister of desiccant to naturally absorb moisture from the waveguide system and collect it in the dehydrator.

Replacing the contents of the canister every 12-18 months keeps moisture levels in the waveguide system low to prevent corrosion from forming.

For more information feel free to call us and discuss your needs with one of our design engineers.

See Also:

Waveguide Components Menu

| Waveguide Passive Dehydrators | |

|---|---|

|

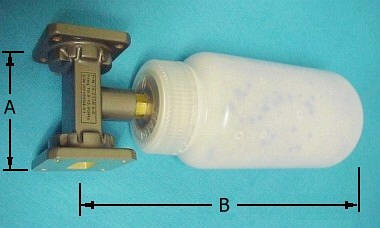

• Low cost |

|

Narda-MITEQ Passive Dehydrators provide cost-effective drying of small volume waveguide systems. It can be used for backup dehydration in larger systems, eliminating the need to run a pressurized system on emergency power. Standard Models: Employs a desiccant drying system which lasts 12 to 18 months or more, before needing service depending on environmental conditions and system volume and tightness. The desiccant material is designed to change color over time, indicating a need for regeneration, which is easily accomplished by heating the material in a convection oven. Self-Pumping Models: Narda-MITEQ’s self-pumping passive dehydrator use a check valve that relies on fluctuations in atmospheric pressure and ambient temperature to pressurize your waveguide assembly in a seal system. When the gas pressure inside the waveguide assembly is less than the surrounding atmosphere, a sensitive check-valve opens. This allows air to enter the system, but only after passing through and being dried by the desiccant. When internal pressure is greater than atmospheric, the check valve seals shut thereby maintaining positive system pressure, making our self-pumping model responsive to environmental changes providing dry air circulation within the waveguide Typical Applications for Waveguide systems should be limited to 11 feet in length, or a max of 1 cu. foot for best effectiveness. The Canister Assembly is mounted to the Waveguide Broadwall, and is designed to be mounted with canister facing sideways or down as shown. |

|

| Waveguide Passive Dehydrator / Dryer - Standard Models | |||||

| WG Size | Freq. (GHz) | Standard Model No. | Self-Pumping Passive Dehydrators Model No. |

Length Dim A (inches) |

Dim B Approx. (inches) |

| WR650 | 1.12 - 1.70 | 650-213A-2-2 | 650-214A-2-2 | 4.00 | 8.9 |

| WR430 | 1.70 - 2.60 | 430-213A-2-2 | 430-214A-2-2 | 4.00 | 8.3 |

| WR340 | 2.20 - 3.30 | 340-213A-2-2 | 340-214A-2-2 | 4.00 | 8.1 |

| WR284 | 2.60 - 3.95 | 284-213A-6-6 | 284-214A-6-6 | 4.00 | 7.9 |

| WR229 | 3.30 - 4.90 | 229-213B-2-2 | 229-214B-2-2 | 4.00 | 7.8 |

| WR187 | 3.95 - 5.85 | 187-213A-6-6 | 187-214A-6-6 | 3.00 | 7.7 |

| WR159 | 4.90 - 7.05 | 159-213B-2-2 | 159-214B-2-2 | 3.00 | 7.7 |

| WR137 | 5.95 - 8.20 | 137-213B-2-2 | 137-214B-2-2 | 2.25 | 7.6 |

| WR112 | 7.05 - 10.0 | 112-213B-6-6 | 112-214B-6-6 | 2.25 | 7.5 |

| WR90 | 8.20 - 12.4 | 90-213A-6-6 | 90-214A-6-6 | 2.25 | 7.5 |

| WR75 | 10.0 - 15.0 | 75-213B-6-6 | 75-214B-6-6 | 2.25 | 7.6 |

| WR62 | 12.4 - 18.0 | 62-213B-6-6 | 62-214B-6-6 | 2.25 | 7.4 |

| WR51 | 15.0 - 22.0 | 51-213B-6-6 | 51-214B-6-6 | 2.25 | 7.4 |

| WR42 | 18.0 - 26.5 | 42-213B-6-6 | 42-214B-6-6 | 2.25 | 7.3 |

| WR34 | 22.0- 33.0 | 34-213B-6-6 | 34-214B-6-6 | 2.25 | 7.3 |

| WR28 | 26.5 - 40.0 | 28-213B-6-6 | 28-214B-6-6 | 2.25 | 7.3 |

|

* The Standard Model Numbers above are the most common parts ordered for size, material and flange. However, these models can easily be altered for your needs by using the Model # code system to the left. |

||||||||||||||||||||||||||||||||||||||||||

| Replacement Desiccant Cartridges For Passive Dehydrators / Dryers | ||

|---|---|---|

| Description | Model No | Outline Dwg |

|

Extra canisters can be ordered using the model number to the right. This is the standard spare canister for all waveguide sizes. |

PHC100 | Dwg |

|

Extra canisters can be ordered using the model number to the right. This is the standard spare canister for all waveguide sizes with Check Valve |

PHC100V | Dwg |